Quality and Service

Current Location:Home > Quality and service > Quality inspection equipment

Current Location:Home > Quality and service > Quality inspection equipment

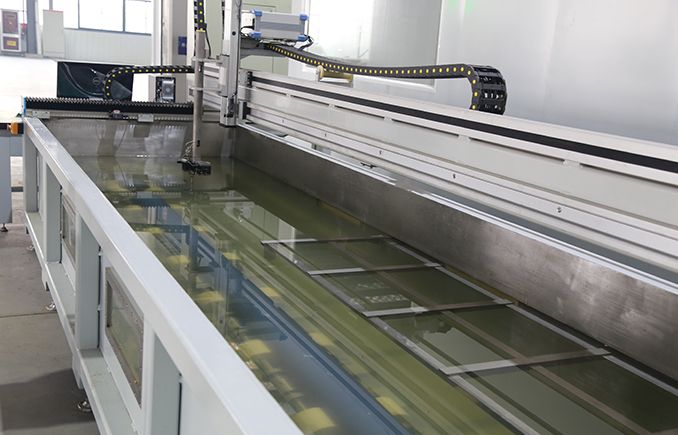

ESCAN Ultrasonic C Scan Inspection System:

A non-contact ultrasonic testing method is used to probe the presence or absence of defects in the water by filling a water layer with a certain thickness between the probe and the workpiece and passing the ultrasonic layer first through the water layer and then entering the workpiece. The specific test object is (various targets, welding layer)

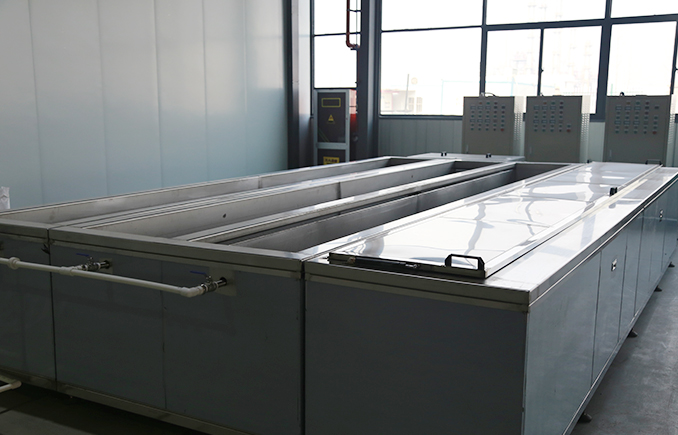

Ultrasonic cleaning machine:

The ultrasonic wave propagates in the liquid, causing the liquid and the cleaning tank to vibrate at the ultrasonic frequency, and the liquid and the cleaning tank vibrate with their own natural frequency to achieve the cleaning of the sample. The specific specifications are: 1000*4000mm, two cleaning tanks, and an oven, which can complete the cleaning of target materials of various specifications.

laser marking machine:

The use of fiber lasers, standard operating range 110*110mm, equipment laser head can be rotated 360 °, can be tilted marking, so that the laser can slash the stainless steel tube, titanium tube within 2 cm, and the copper back plate marking, the effect is beautiful ,profession.

Optical microscope:

The maximum magnification 4000X, can effectively observe a variety of powder morphology.

10000 balance, high precision electronic scale, four-probe resistivity tester:

Accurate and effective measurement of various aspects of the performance of the sample.

Better size2000 laser particle sizer:

The detection range (0.02-2000μm) can accurately and rapidly analyze the particle size distribution of different specifications.

Powder comprehensive tester:

The powders were tested for angle of repose, collapse angle, difference angle, plate angle, bulk density, tap density, degree of compression, homogeneity, and fluidity index. Fully automatic operation reduces the errors caused by the environment and the factors that make the test more accurate.