Technology and Product

Current Location:Home > Technology and Product > Major Equipment

Current Location:Home > Technology and Product > Major Equipment

|

prev

next

|

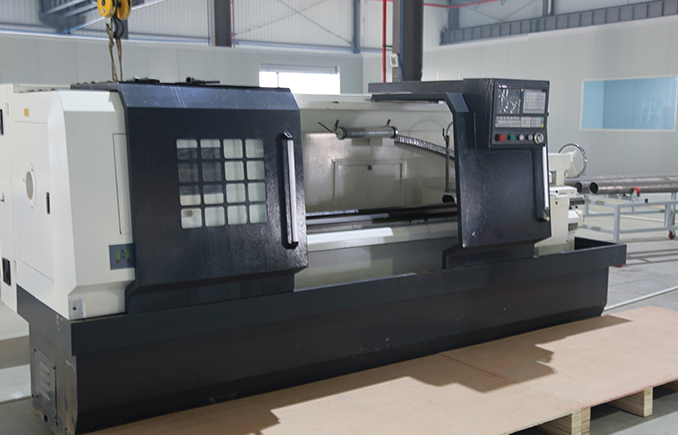

Product name:CNC latheTime:2018-4-3 11:00:27 |

| Product introduction | |

|

CNC lathe characteristic: Due to the configuration of the GSK980TA CNC system, the machine can send and receive various signals to control the automatic machining process. Ultrasound quenching process is adopted for the bed rail, which has strong wear resistance, high spindle rotation accuracy, good shock resistance, and high cutting performance. The vertical and horizontal ball screws are driven by a stepper motor or a servo motor, and the dynamic response is excellent. Low noise, strong adaptability to large, medium and small batch, multi-variety, multi-species components, stable and reliable quality. Can automatically complete a variety of parts inside and outside the circular surface, grooving, any cone surface, curved surface, male and female cylindrical, conical thread and other processes. Technical Parameters: Maximum swing diameter 630mm on the bed, maximum swing diameter 350mm on the slide, maximum workpiece length 1500mm, spindle speed series 18, spindle speed range 14-750 r/min, main motor power 7.5KW, spindle aperture 105mm, positioning accuracy (X / Z) X: 0.025 Z: 0.03 mm, repeatability positioning accuracy X: 0.01 Z: 0.015 mm, tool post type and tool station vertical 4 stations, horizontal 6 station, tool shifting time 1S, knife Feed minimum setting unit X: 0.005 Z: 0.01 mm, tool carrier rapid traverse speed (X/Z) X: 2 Z: 4 m/min, tool post positioning repeat positioning accuracy 0.01 mm, workpiece accuracy (roundness , flatness) 0.003mm, workpiece surface roughness 1.6um, tailstock sleeve diameter 100mm, tailstock sleeve stroke 25mm.

|

|

Case introduction

Case introduction

CNC lathe

characteristic:

Due to the configuration of the GSK980TA CNC system, the machine can send and receive various signals to control the automatic machining process. Ultrasound quenching process is adopted for the bed rail, which has strong wear resistance, high spindle rotation accuracy, good shock resistance, and high cutting performance. The vertical and horizontal ball screws are driven by a stepper motor or a servo motor, and the dynamic response is excellent. Low noise, strong adaptability to large, medium and small batch, multi-variety, multi-species components, stable and reliable quality.

Can automatically complete a variety of parts inside and outside the circular surface, grooving, any cone surface, curved surface, male and female cylindrical, conical thread and other processes.

Technical Parameters:

Maximum swing diameter 630mm on the bed, maximum swing diameter 350mm on the slide, maximum workpiece length 1500mm, spindle speed series 18, spindle speed range 14-750 r/min, main motor power 7.5KW, spindle aperture 105mm, positioning accuracy (X / Z) X: 0.025 Z: 0.03 mm, repeatability positioning accuracy X: 0.01 Z: 0.015 mm, tool post type and tool station vertical 4 stations, horizontal 6 station, tool shifting time 1S, knife Feed minimum setting unit X: 0.005 Z: 0.01 mm, tool carrier rapid traverse speed (X/Z) X: 2 Z: 4 m/min, tool post positioning repeat positioning accuracy 0.01 mm, workpiece accuracy (roundness , flatness) 0.003mm, workpiece surface roughness 1.6um, tailstock sleeve diameter 100mm, tailstock sleeve stroke 25mm.

|

UP:Surface Grinder

NEXT:CNC internal and external cylindrical grinding machine |

Return list |